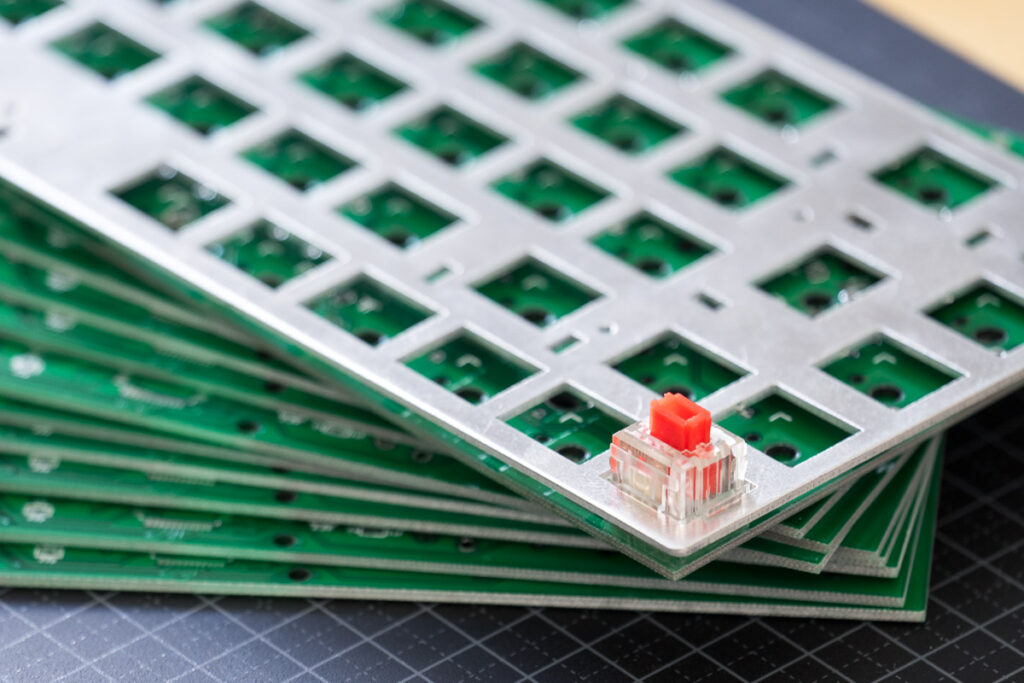

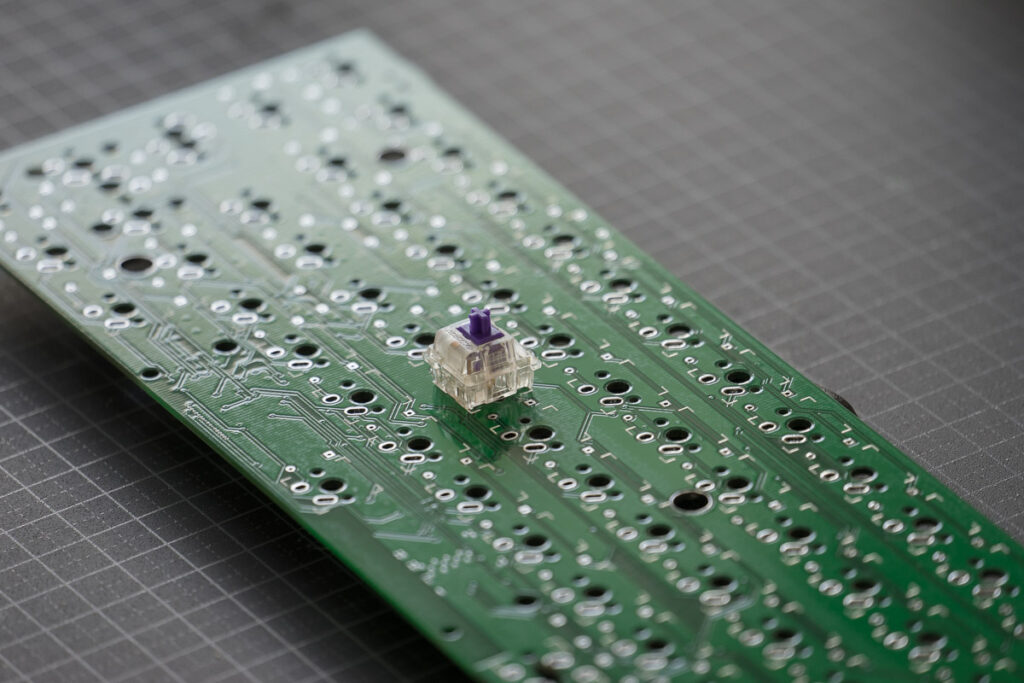

The boards came in the mail yesterday, and I haven’t had the time to solder one up, let alone test one. This post is just to keep you guys updated. I’m eager to build one, so I hope to get back to you soon.

Handy computers

Computers can make anything nowadays. Photo editing, CAD, 3D rendering, CNC-milling, 3D-printing and much more. I used KiCad to design a circuit board, and it was no trouble at all. I just made a schematic, drew in where tracks should go, where components will be and sent it off to be made for me. A lot easier than wiring the keyboard myself. And probably just as cheap, definitely cheaper if you account for time.

That said, I do want to finish my hand soldered keyboard, just to have made one once. And maybe I should do a couple, to be able to give an informed opinion.

I will be soldering a bit for this to work too. More than 80 components per board, not counting switches. With a prototype series of ten, that makes about 800 components. I guess I will practise my soldering.

What I’ve learned

- Put all the holes in before you do any tracking. Holes swallow tracks.

- Try to put all components in place before you do any tracking. In our case, key layout rules above anything else.

- Try to finish the schematic before you draw your PCB. Adding components and connections after the fact is a hassle we don’t need.

- There is no mystery to making circuit boards. It’s just electronics in a handy form. Remember the basics.

- Computers can really do anything. Let them do the pick and placement of your surface mount components too if you can.

Leave a Reply