This is not what I’m trying to do, but I’m glad I did it.

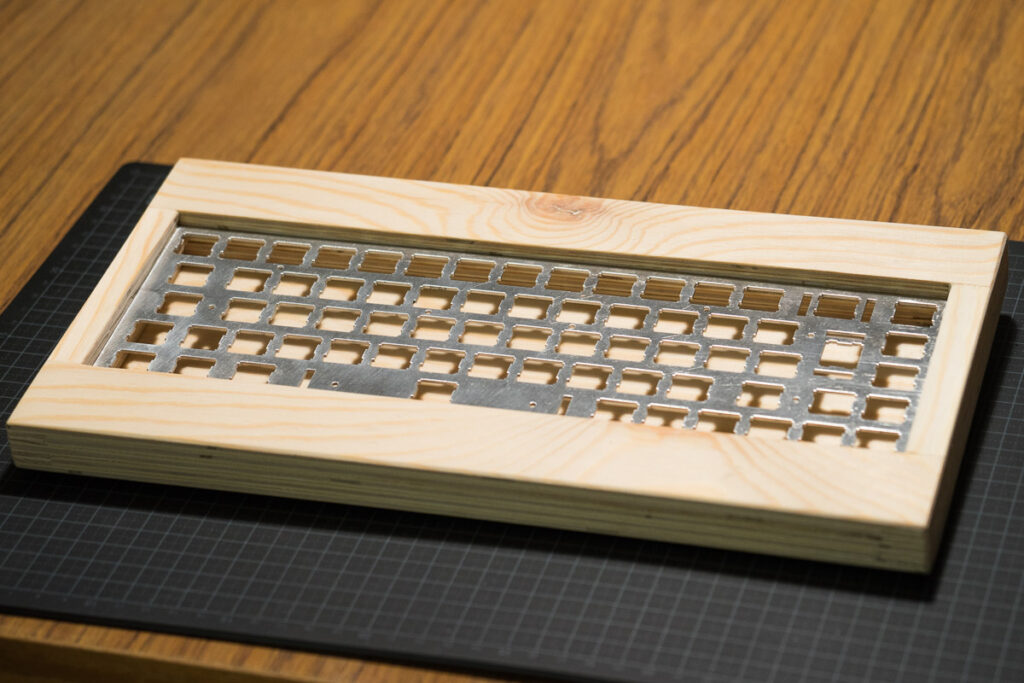

My general idea is to make some really awesome cases. This isn’t one of those. It’s much to big, unbalanced and downright ugly. But it will make for a great prototype. There’s plenty of space inside to accommodate for electronics, batteries, alterations and mistakes. Above all it’s something to touch, feel and see.

And I’ve done my best! That’s some serious (s)crapwood, that is! Made to precision specs by hand. A slow and time tested process for master carpenters in their quiet, airy and light workshops. Think handsaws and box planes. I’m actually rather pleased. But anyway… This is nothing like the cases I’m designing and hope to bring into production eventually.

General idea

I’ve made more than one case in Fusion 360, but this one just uses some of the inner measurements of those designs. The rest is done by feel. The angle of the case is fixed, and the over sized frame is for holding electronics. It’s made from layers of 4 mm plywood.

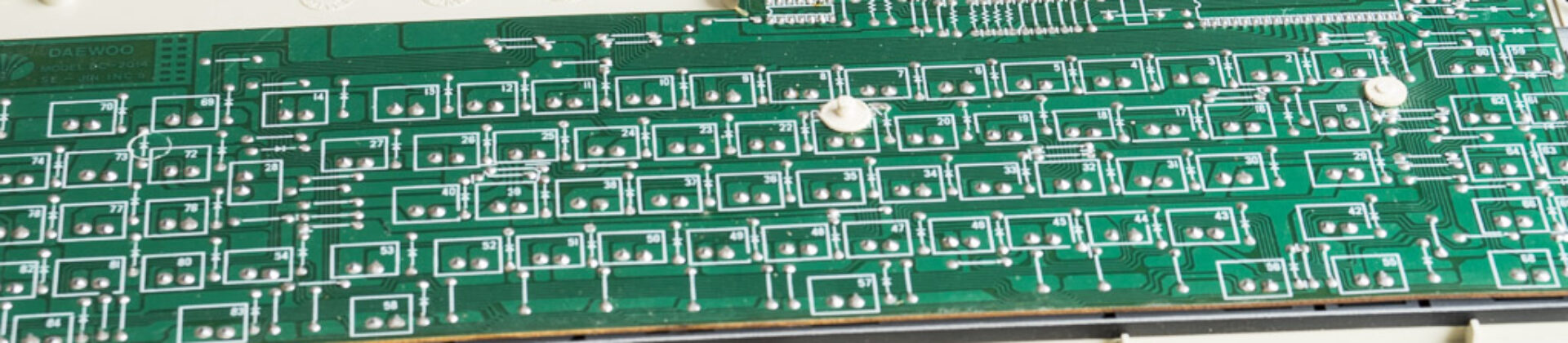

I know the switches on a PCB (eventually) will need a case that’s 8 mm deep, but to fit my soldering, a micro controller board and a battery I made the inside 12 mm deep. With the bottom it’s 16 mm high before I even lay a frame around the keycaps. That adds 8 more millimetres to the design with a total of 24 mm!

That’s one third more than I hope to make the final version, but for now…

What have I learned

- You can’t work with too small tolerances

- Design has to be simple and straightforward

- Wood shrinks and expands, allow for some play

- This will take some time, more than I think

O, and by the way

This is not a workshop…

Leave a Reply